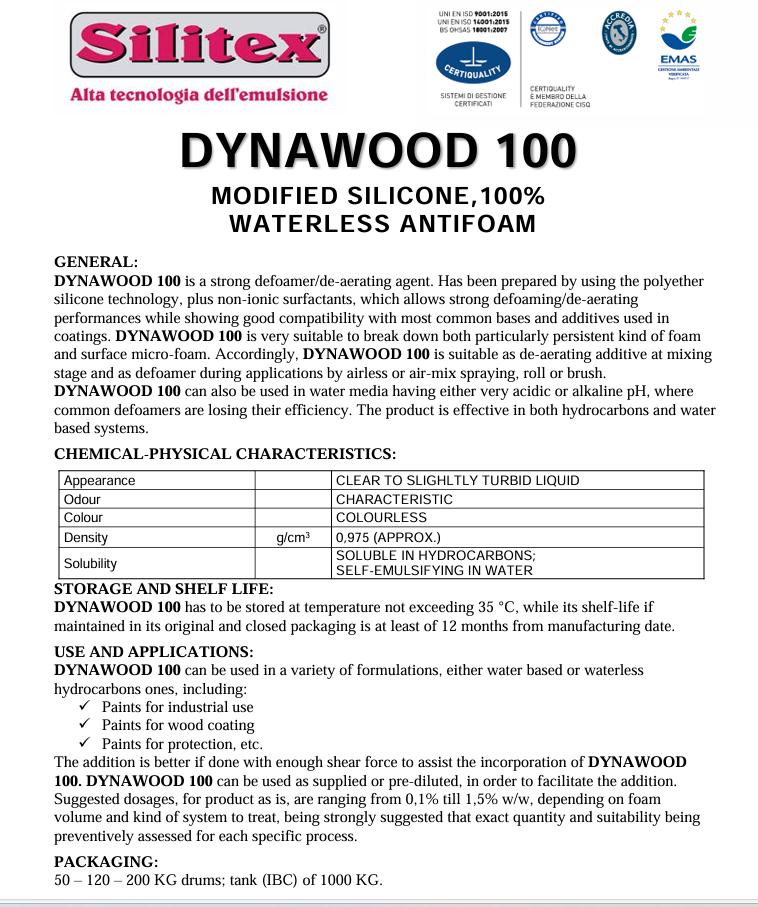

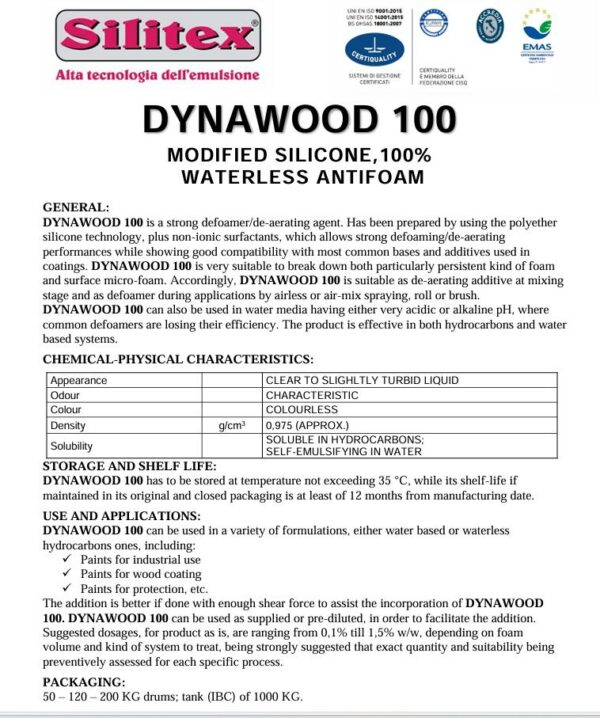

DYNAWOOD 100

MODIFIED SILICONE,100%

WATERLESS ANTIFOAM

GENERAL:

DYNAWOOD 100 is a strong defoamer/de-aerating agent. Has been prepared by using the polyether

silicone technology, plus non-ionic surfactants, which allows strong defoaming/de-aerating

performances while showing good compatibility with most common bases and additives used in

coatings. DYNAWOOD 100 is very suitable to break down both particularly persistent kind of foam

and surface micro-foam. Accordingly, DYNAWOOD 100 is suitable as de-aerating additive at mixing

stage and as defoamer during applications by airless or air-mix spraying, roll or brush.

DYNAWOOD 100 can also be used in water media having either very acidic or alkaline pH, where

common defoamers are losing their efficiency. The product is effective in both hydrocarbons and water

based systems.

CHEMICAL-PHYSICAL CHARACTERISTICS:

| Appearance | CLEAR TO SLIGHLTLY TURBID LIQUID | |

| Odour | CHARACTERISTIC | |

| Colour | COLOURLESS | |

| Density | g/cm3 | 0,975 (APPROX.) |

| Solubility | SOLUBLE IN HYDROCARBONS; SELF-EMULSIFYING IN WATER |

STORAGE AND SHELF LIFE:

DYNAWOOD 100 has to be stored at temperature not exceeding 35 °C, while its shelf-life if

maintained in its original and closed packaging is at least of 12 months from manufacturing date.

USE AND APPLICATIONS:

DYNAWOOD 100 can be used in a variety of formulations, either water based or waterless

hydrocarbons ones, including:

✓ Paints for industrial use

✓ Paints for wood coating

✓ Paints for protection, etc.

The addition is better if done with enough shear force to assist the incorporation of DYNAWOOD

100. DYNAWOOD 100 can be used as supplied or pre-diluted, in order to facilitate the addition.

Suggested dosages, for product as is, are ranging from 0,1% till 1,5% w/w, depending on foam

volume and kind of system to treat, being strongly suggested that exact quantity and suitability being

preventively assessed for each specific process.

PACKAGING:

50 – 120 – 200 KG drums; tank (IBC) of 1000 KG.

Reviews

There are no reviews yet.